Keg Project

Keg Project

Product design / UX Reasearch

The project initially aimed to investigate needs and requirements within the pub and restaurant industry. It sought to understand the functionality of beer keg handling, identify user challenges, and design a tailored solution.

Team

3 MEMBERS

Time

2021 NOV - 2022 MARS

Role

Industrial Designer, Field

Researcher

Tools

Blender

Background

Visiting pubs and restaurants is a cherished pastime for Swedes, offering socializing and enjoyment of food and drinks, especially beer. Over time, beer storage has evolved from wooden casks to aluminum and plastic kegs. Despite beer's popularity, the process of serving it remains unfamiliar to many. Typically, a keg is connected to a tap for dispensing into a glass. Systems and keg choices vary by supplier and venue layout. Managing the large keg volumes requires careful storage and handling in the busy hospitality environment, posing challenges for staff and equipment alike.

Purpose

The initial aim of this project was to explore the needs and requirements within the pub and restaurant industry, with a pilot study specifically focusing on the handling of beer kegs. Thus, the project aimed to investigate how beer keg handling functions, identifying the problems and challenges faced by users and design a solution.

Final product

Process

Phase 1 - Initial research

Phase 2 - Process & analysis

Phase 3 - Concepts & Iteration

Initial research

An pilot study explored operational challenges in pubs and restaurants through questionnaires and interviews, revealing issues in serving, storage, and beer keg handling. A literature review further examined keg pricing, types, and ergonomic studies, guiding our project's direction.

Pilot at j.a pripps

Our initial pilot study at J.A. Pripps explored the pub and restaurant industry's dynamics with minimal disruption to operations. Using a tailored questionnaire and semi-structured staff interviews, we gained insights into workflows, routines, and team dynamics. Key issues were identified in serving, storage, and beer keg handling. Consequently, our focus shifted to beer keg management—a crucial yet often overlooked aspect of hospitality operations.

Literature review

In complement to our pilot study, a literature review was conducted to address lingering questions, especially about beer kegs and their systems. We explored potential price variations among keg types, identified any kegs not highlighted in our user research, and reviewed ergonomic studies related to beer kegs. This review drew from scientific articles accessed through the Chalmers Library database and regulatory guidelines from the Swedish Work Environment Authority.

Process & analysis

After the pilot study a new template with general questions about beer kegs and how pubs handle them was created. A first field study was then conducted, visiting 12 different establishments on in Gothenburg, where various types of beer systems, kegs, and their handling were examined.

Identified problem areas

Users struggled with identifying kegs due to similar appearances and small labels, causing mistakes and extra lifting. Moving 35 kg kegs, especially over long distances or up stairs, was a major issue. Carlsberg's plastic keg system is user-friendly, but logistical constraints limit its use.

The Design of the keg

Many users expressed difficulty identifying which keg contained which beer. Most kegs from the same supplier look identical, with only small labels to distinguish them, leading to frequent mistakes and unnecessary lifting. Another issue is the label placement on the top of the kegs, making it impossible to identify them when stacked. This, combined with the small and similar-looking labels, results in avoidable lifting and wasted time. This labeling problem affects all keg types studied in the user study.

Transportation

In various interviews, it emerged that moving the kegs was considered the most problematic aspect of handling them in most restaurants. The kegs, weighing around 35 kg, often need to be carried long distances, up stairs, or lifted to heights up to 150 cm. This was seen as heavy and troublesome, especially when moving many kegs at once. In some cases, staff had to move up to 16 kegs at a time during deliveries, described as "like a workout," from the loading area to the basement storage.

CHANGING KEG

Aluminum keg exchanges were similar across many locations, with slight variations. Different systems were used for tapping kegs, notably at Brödernas where kegs were tapped under the bar counter, and at Koks where a storage cabinet housed nine kegs, six of them tapped. Kegs were often stacked to streamline exchanges, with the top keg connected for efficient swapping by disconnecting the empty top keg, lowering it, and connecting the lower one.

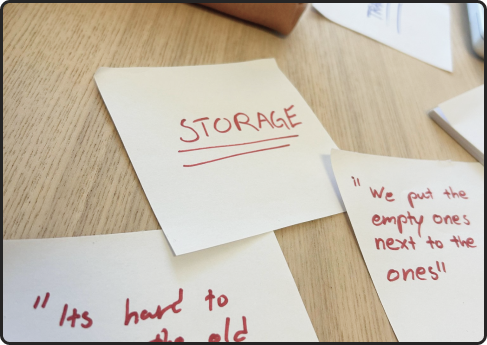

STORAGE

Storage of filled beer kegs varied across cellar rooms, bar backrooms, and under-tap spaces, often leading to stacking in corridors and alongside filled kegs, which posed logistical challenges and hindered staff efficiency, especially during busy times; empty kegs, including Carlsberg's compressed types, further complicated matters with box storage impacting venue flow and operational efficiency.

Keg system

The aluminum keg beer system used in the hospitality industry is complex and poses challenges due to its steep learning curve and lack of immediate feedback, contributing to staff stress and potential errors. Carlsberg's plastic keg system offers improved user-friendliness with better feedback on operational status, but venue constraints with supplier choices and logistics remain significant hurdles, affecting system integration and staff training efforts, despite potential cost coverage by suppliers.

Analysis

Following our study, we employed a fishbone diagram and thematic analysis to analyze the identified issues. The fishbone diagram helped identify root causes such as challenges in keg identification and the physical strain of moving heavy kegs. Thematic analysis revealed recurring themes including labeling difficulties and the physical demands placed on staff.

Thematic analysis

In the first stage of our KJ analysis, we reviewed interview transcripts and condensed the content, potentially missing important details chosen by the group. Overall, the KJ analysis effectively summarized all project information, giving us a comprehensive view of interview findings and prompting discussions on recurring issues and unique challenges in some restaurants.

Fishbone analysis

After the KJ analysis, we conducted a fishbone analysis to find connections and causes within the categories identified. The fishbone analysis was much quicker than the KJ analysis but yielded limited new information. However, the resulting diagram was highly beneficial for creating the requirements, as it provided a clear overview of the root causes of various problems, simplifying the process of addressing them.

Requirements profile

change of keg

1. Lifting during exchange should not exceed 25 kg.

2. An exchange should be ergonomic to perform.

3. The system should provide the user with instructions on how to perform an exchange.

4. Feedback should be given to the user when an exchange is performed correctly or incorrectly.

5. There should be a low risk of mishandling during an exchange.

6. An exchange should be possible within one minute.

Transportation

7. Kegs should be moved efficiently and ergonomically from truck to storage space, up to 20 kegs.

8. Kegs should be moved ergonomically on stairs.

9. Kegs should be moved efficiently and ergonomically from storage to exchange location.

10. Moving a keg from storage to exchange location should take no more than two minutes.

Design

11. Kegs should be ergonomically manageable from 0 to 150 centimeters in height.

12. It should be easy to identify the contents of different kegs, even when stacked.

Storage

13. Empty kegs should allow for space-efficient storage options.

14. Users should not need to handle used kegs themselves.

15. Filled kegs should allow for space-efficient storage options.

System

16. Users should receive feedback on errors during exchanges or other system failures.

17. Users should have a wide range of options available.

18. Users should have easy access to system servicing.

Early drafts

The concepts in the images below were the ones we felt had the strongest characteristics in line with the functional listing and specifications. We chose to create physical models of these concepts, as well as clearer and more informative sketches.

Pirran

Saxen

pumpen

User evaluation

Before gathering user feedback, we created a questionnaire with relevant questions and scenarios. Users were asked to describe how they would use the product without additional instructions. During the feedback sessions, we explained the components and functionalities of each concept in detail. We presented scenarios and asked users to choose which concept they preferred. We then held discussions where users shared the advantages and disadvantages of each concept and provided suggestions and ideas for improving the product design.

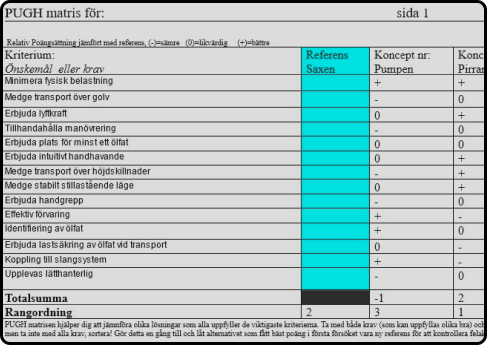

Pugh martix

Based on the Pugh matrix, Pirran emerged as the top performer for meeting functional requirements, particularly for its stability over longer keg transport distances. Users favored Pirran for its stability over longer keg transport distances, while Pumpen was preferred for its compactness in smaller spaces. Pumpen was selected for development, focusing on innovative solutions not found in existing products, contrasting Pirran's similarity to established market offerings. The team refined Pumpen's features to precisely meet the identified application needs.

Identified problem areas

“Pumpen” is an innovative lifting device designed to help users lift and move beer kegs in an ergonomic and safe manner. This solution combines a robust construction with easy-to-maneuver features to minimize physical strain and maximize efficiency in handling beer kegs.

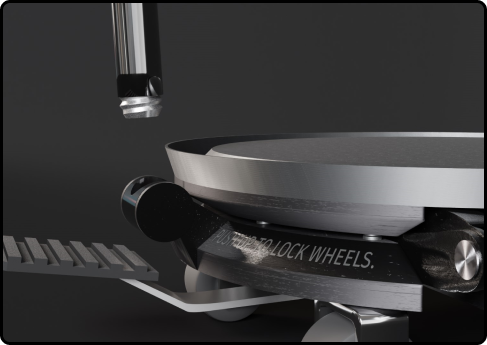

Round Plate with Small Wheels

The base of Pumpen consists of a round plate equipped with four small wheels, making it easy to roll and position the unit. The wheels are designed to provide smooth and effortless movement, allowing the user to navigate tight spaces and uneven surfaces with ease. This feature ensures that the unit can be precisely positioned wherever needed, enhancing the overall functionality and convenience of the lifting device.

Scissor Lift Mechanism

In various interviews, it emerged that moving the kegs was considered the most problematic aspect of handling them in most restaurants. The kegs, weighing around 35 kg, often need to be carried long distances, up stairs, or lifted to heights up to 150 cm. This was seen as heavy and troublesome, especially when moving many kegs at once. In some cases, staff had to move up to 16 kegs at a time during deliveries, described as "like a workout," from the loading area to the basement storage.

Foot Pump

The foot pump is a central component of the lifting mechanism, designed to offer maximum efficiency and ease of use. By utilizing leg muscles instead of the back, the foot pump enables the user to lift the beer keg in a more ergonomic manner. This reduces strain on the back and lowers the risk of musculoskeletal injuries, making it safer and more comfortable to operate over extended periods.

Ergonomic Handle

A detachable handle can be attached to the round plate, enhancing the mobility and maneuverability of the unit. This handle is specifically designed to be ergonomic, ensuring a comfortable grip and reducing strain on the user's hands and wrists. Additionally, if you have multiple units of the same plate, the handle can be used interchangeably with each one, providing flexibility and convenience. This makes it easy to move the plate and the keg around, offering greater control and stability during transportation.